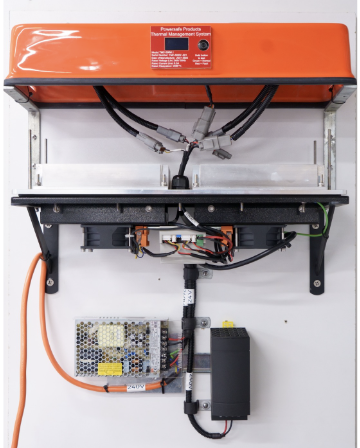

Switchboard - Thermal Management Control - (TMC)

Control and maintain internal cabinet temperature and humidity to ensure internal components (RCD, Circuit Breakers) remain within the operating temperatures of manufacturer’s specification to comply to AS/NZS 61439

The range of Powersafe Thermal Management Control (TMC) Systems has been designed to provide an IP65 closed loop cooling system for use on equipment exposed to the harsh Australian environment. Available in three sizes; 200W, 500W, 800W, The Powersafe TMC range offers a robust IP65 solution for switchboard thermal control.

IP65 tested and rated for outdoor and indoor applications.

· Display showing internal temperature and humidity

· Fitted with controller for fan speed control and monitoring (PWM)

· Test button and OLED display for visual reference

· Minimal wiring for installation.

· Condensation, under temperature and humidity control and heater supplied

· GRP fibreglass cover fitted with UV testing to AS61439.

Electrical enclosure closed loop heat exchanger thermal management system – IP65

Suitable for: Outdoor environments, harsh environments, and indoor environments where closed-loop cooling is required. Can be used in metal, GRP and plastic enclosures.

Can be fit to the top or the side of electrical cabinets.

Also available: Full ACS63 TMS

TMS Lid Only – Did you know that if you are already a Powersafe customer and have any of our LB01 or MB01 Boards, our Thermal Management System lid can replace the existing lid to convert your lower amp powerboard into a more versatile thermally managed solution.

MINING

Construction

defence

events

Heat is the Enemy to Electrical Components

Heat is both a by-product and one of the greatest enemies of electrical and electronic components. If not dissipated, this heat has the potential to cause early failures and malfunctions.

The primary purpose of electrical enclosures is to provide protection and safety for the components they house. If an enclosure is properly cooled, the components within can have a long and useful life. Without proper cooling, however, the components in these enclosures can be subject to damaging heat, shortening their longevity and reliability.

Although individual manufacturer’s specifications vary, the majority of electrical distribution and control equipment is designed to operate properly and achieve normal life expectancy under ambient air conditions ranging from 25 – 40°C

Poor Thermal Management Can Lead To:

Noncompliance with the standards

Noncompliance with the standards

Shortened equipment life

Shortened equipment life

Catastrophic component failure

Catastrophic component failure

Higher maintenance costs

Higher maintenance costs

Unexpected equipment shutdown

Unexpected equipment shutdown

Intermittent fluctuations in I/C-based devices

Intermittent fluctuations in I/C-based devices

Fire hazard

Fire hazard

These Issues Lead To

- Maintenance and replacement component costs

- Downtime

The real cost of not having thermal management is not a known cost upfront but will quickly add up in downtime and maintenance and the cost of replacement of components and labour to do the repairs.

What Would A Thermal Management Solution Save You?

What does it cost your company to have power distribution problems due to overheating of your switchboard and power distribution equipment?

WHY THERMAL MANAGEMENT:

To Understand Why Thermal Management Is Important Let’s Discuss The 3 Most Common Types Of Thermal Management:

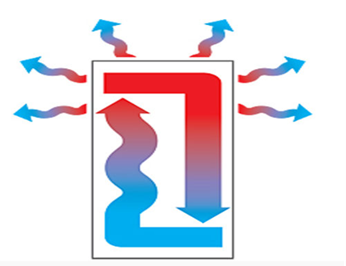

Method 1 : Natural Convection – No Thermal Management

Cheapest method at point of purchase but maintenance of internal components will be greater if the enclosure temperature becomes greater then the manufacturer of the components operating temperature and will not meet the required standards in this application.

Pros:

- Inexpensive at the initial purchase

Cons:

- Limited cooling capacity

- May not meet the standards (AS/NZS 3000 & 61439) – If the heat loss of the components is greater than the enclosure can dissipate, then components will operate at temperature greater than the manufacturers ratings after running for a period. Which will lead to:

- Higher maintenance due to component replacement – components will have a far shorter life span.

- Nuisance tripping of the circuit breakers as they will trip below there rated current as the temperature increase

- Potential for catastrophic failure of components and fire hazard.

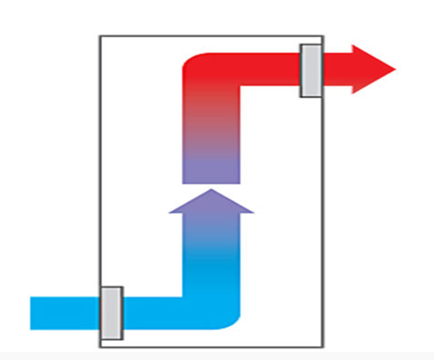

Method 2: Open Loop Cooling

Ventilates the cabinet by circulating fresh ambient air and exhausting heat away for the components.

Not the best solution due to dust ingress but far better for thermal efficiency then the method 1 of natural convention. Will increase the lifespan of internal components but is subject to allowing moisture and dust ingress into the enclosure.

Pros:

- Inexpensive

- Works well in a cool, dust and moisture free environment

Cons :

- Requires filters that need to be maintained and cleaned regularly

- Not suited to environments that are exposed to rain or dusty conditions for long durations

- Will ingress some dust into the system eventually (The better the filter and controller the less dust ingress will occur)

- Not suited to harsh environments – can expose internals components to dust, dirt , water (moisture) , metal filings and corrosive fumes (ie diesel exhaust etc)

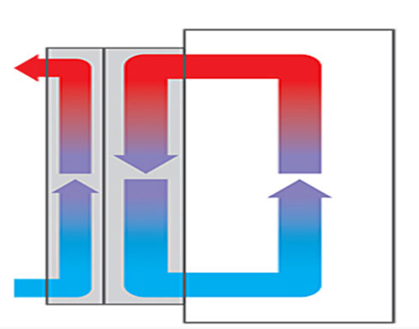

Method 3: Closed Loop Cooling

Closed loop cooling is where a sealed enclosure cooling does not allow outside elements inside the enclosure. Best method for operating in high temperatures and or if there is solar gain (exposed to direct sunlight) or when the enclosure is deployed in harsh environments.

Pros :

- Generally, is more efficient in higher ambient then other methods of cooling

- Limited maintenance on the cooling system

- Allows for no dust or moisture to be introduced into the enclosure.

- Will dramatically increase the life of the components within the enclosure, therefore creating a far cheaper outcome over the lifespan of the board.

- When correctly selected, enables full load amps (RDF of 1) to be used, without overheating components and will meet the required standards – AS / NZS 3000 & AS/NZS 61439

Cons :

- Expensive compared to other methods at the point of purchase. Due to the increased life span of components and maintenance will over the lifespan of the board will be cheaper than other alternatives where thermal management is required due to lower maintenance and far greater component lifespan within the enclosure.

we maintain the highest level of safety in all products we manufacture

FAQ'S

If you are drawing more current, then what the RDF factor on the power board is rated by the manufacturer then, without thermal management you run the risk of overheating the assembly which can lead to premature failure or catastrophic failure of components.

AS/NZS 61439 tells us that for boards greater than 125 Amps the assembly must be tested as a complete system – the old standards (AS/NZS 3439 ) allowed Type testing or partial type testing in “Free Air” .

Under 125 Amps, the assembly is not required to be tested as a complete assembly, but verification can be achieved largely by assessment, including adherence to manufacturers instructions.

The only true way to do the assessment on an outdoor enclosure is to test the assembly and make sure it does not exceed the components rated ambient operating temperature. In an outdoor enclosure the operating temperature of most RCD and RCBO can be exceeded in a very short period of running time.

If the load on the assembly is going to be greater than the RDF rating without thermal management, YES it is, for compliance to the standards, lifespan of the components and the safety of the operation of the assembly.

The cost of replacing defective components over the lifespan of the assembly will generally far out way the cost of thermal management at the time of purchase.

The rated diversity factor is the per unit value of the rated current, assigned by the assembly manufacturer, to which the outgoing circuits of an assembly can be continuously and simultaneously loaded taking into account the mutual thermal influences.

Basically, if you had a 100-amp board, with a RDF of 0.5, then you can load the board to 50 amps and remain in a “safe” operating limit without overheating the assembly. Beyond this (particularly if done regularly) you will be stressing the components, causing premature failure or worse still – catastrophic failure.

Damaged circuit breakers (from overheating) may not perform properly when excessive currents occur. Instead of tripping when excessive or dangerous current occurs, damaged circuits may continue to let electricity flow, leading to overheating and possible arcing and /or electrical fires.

Absolutely… Under Australian standards in AS/NZS 3000 and AS61439 there is a requirement to verify the thermal management and the RDF factor of the circuits that this was tested at.

All electrical and electronic components are subject to failure due to overheating. High temperatures will reduce the lifespan of the components significantly and possibly lead to the component not providing the protection it was designed to do.